ELD Data Diagnostics Events

ELD devices regularly examines its compliance with ELD technical requirements and detect data inconsistencies related to power, data synchronization, missing data, timing, positioning, data recording, data transfer and unidentified driver records requirements. Visual indicators are also sent to the drivers during the event of data diagnostic and remains effective until data diagnostics events are cleared from ELD. Some of these events get cleared by automatically and some will only get cleared once the ELD device is repaired.

1. “Power Data Diagnostic” events.

“Power data diagnostic events” occur when an ELD is not powered or fully functional within one minute of the vehicle’s engine power up and does not remain powered in sync to vehicle’s engine power time.

2. “Engine Synchronization Data Diagnostic” events

“Engine synchronization data diagnostic events” occur when an ELD loses its connectivity to ECM to record updated values for engine power status, vehicle motion status, miles driven, and engine hours within five seconds of the need.

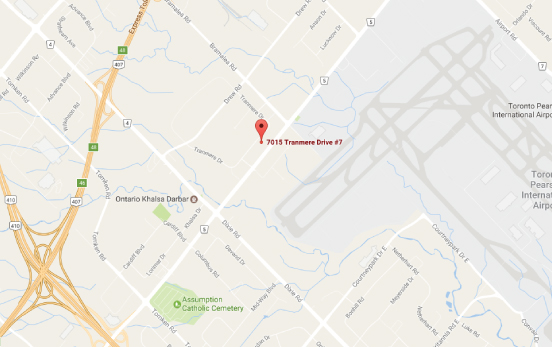

3. “Missing required data elements” data diagnostics event

A “missing required data elements data diagnostic event” occurs when any required data field is missing at the time of its recording.

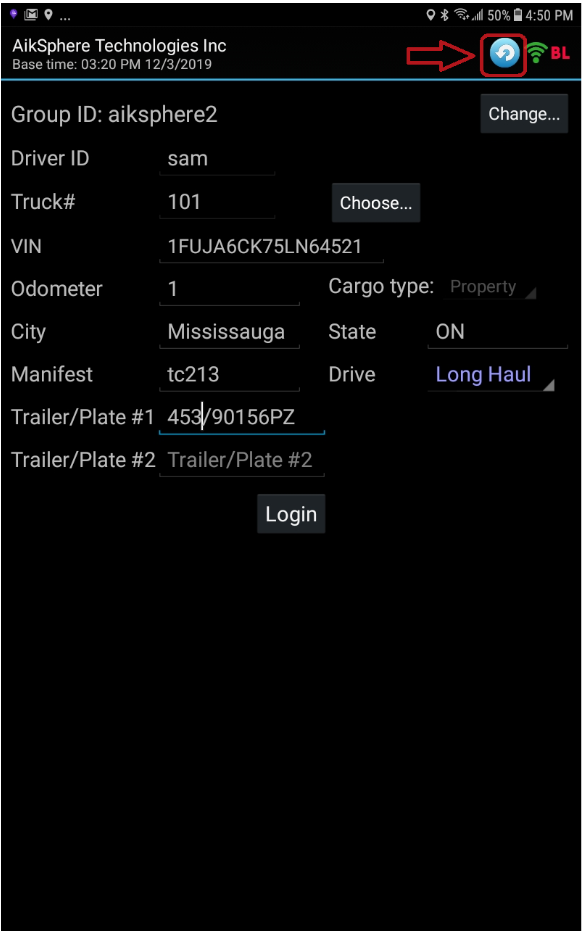

4. “Data Transfer Data Diagnostic events”

A “data transfer data diagnostic event” occurs when the operation of the data transfer mechanism(s) is not confirmed.

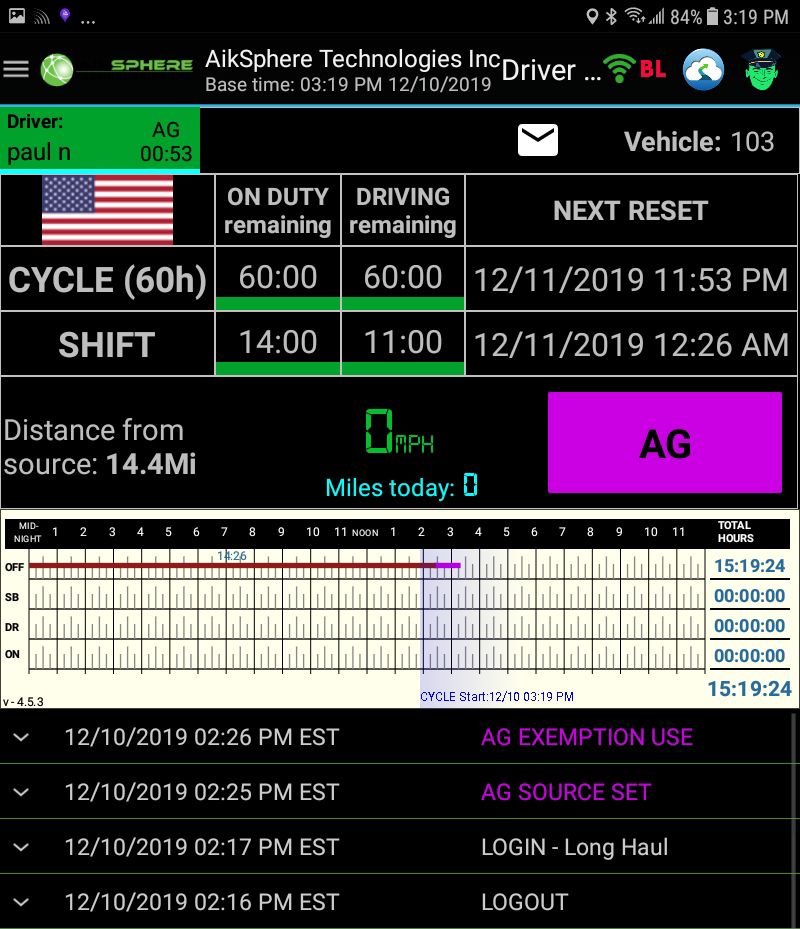

5. “Unidentified driving records data diagnostic event”

An “unidentified driving records data diagnostic event” occurs when more than 30 minutes of driving time for an unidentified driver is recorded within a 24-hour period.

“Unidentified driving data diagnostic event” gets cleared when unidentified driving time for the current 24-hour period and previous 7 consecutive days drops to 15 minutes or less.

Disclaimer- The rules and regulations are subject to change any time. Readers must verify with the authority, FMCSA / MTO and must not rely on the contents of this blog.